Thermoplastic Splint Sheets External Nose Brace Material

Thermoplastic Splint Sheets External Nose Brace Material Parameters: Size: 900*600mm Thickness: 1.6mm/ 2.0mm/2.4mm Perfo

Basic Info.

| Transport Package | Carton Box |

| Specification | 900*600cm |

| Trademark | Aojianyi |

| Origin | China |

| HS Code | 37033609 |

| Production Capacity | 10000PCS |

Product Description

Thermoplastic Splint Sheets External Nose Brace MaterialParameters:

Size: 900*600mm

Thickness: 1.6mm/ 2.0mm/2.4mm

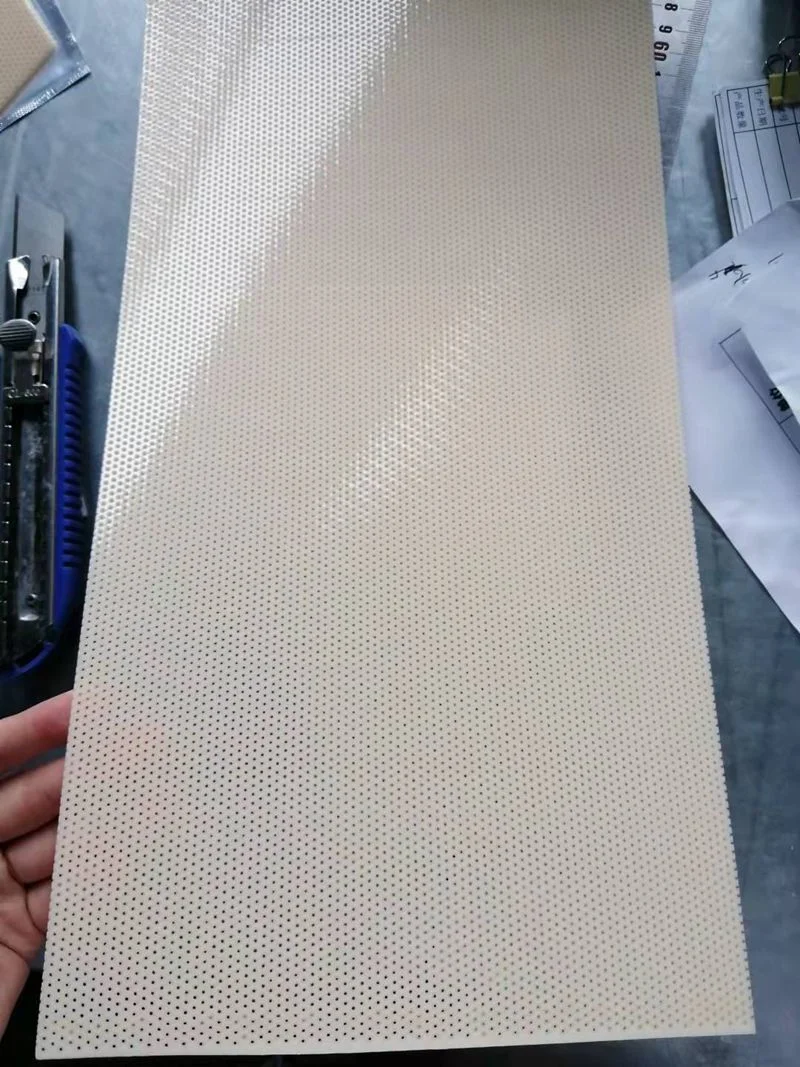

Perforation:micro-perforated , and customized perforated sheets

Colors: Original/ white/ light pink, and customized colored sheets

Features:

1. Mouldable. It could be moulded to the right shape after being activated in hot water.

2. Breathability. The small holes on the thermoplastic plates prevent itching, inflammation, and skin lesions in the patient's skin due to prolonged confinement.

3. Waterproof. Although the thermoplastic sheets could become soft under 65-70 degree water. Actually, it's waterproof like other plastic. You can wear it to the bathroom or even swimming.

4. X-ray transculent. During radiation therapy, the X-ray could be transculent to the skin easily. No need to use other products.

Judgements:

1. A thermoplastic splint is a device used to immobilize, protect and support injuries such as fractures, sprains and strains. Thermoplastic splints differ from traditional plaster casts in that they are lighter, easily molded to fit the body of the individual patient and can be removed for cleaning.

How to use?

Place splint in 65-70°C water for 1-3 minutes or until it becomes pliable. Remove and blot dry with a clean towel. Mold the splint around the body parts (like an arm or leg) until it is the correct shape. As this splint cools, it will harden into a rigid, protective covering.

Send to us